AGRICULTURAL SUBSTRATES TO BIOMETHANE PROJECT

The project will produce bio methane gas from biomass generated via locally sourced agricultural by-products.

The biomass is fermented with special enzymes which produce a biogas consisting of 55% methane and 45% carbon dioxide.

The bio methane results from the upgrading and cleaning of the biogas generated from the biomass.

Although there is a rise in the use of electricity powered vehicles compared with the more traditional petrol and diesel alternatives, automotive analysts forecast that it will take a considerable length of time before electric or hydrogen vehicles take a significant market share of the estimated 1.4 billion cars in the world.

This means that there will be a long “guaranteed” market for biomass based fuels.

Italy has approximately 1 million vehicles running on compressed natural gas. This is the highest percentage in Europe and this number is expected to increase.

In 2016, Italy exceeded all European countries in terms of the number of passenger vehicles utilizing Compressed Natural Gas and the number of Compressed Natural Gas refueling stations.

.

NGV Italy. Source GVR quoted in ‘The Compressed Natural Gas Italian Market.’ Natural Gas Vehicle Alternative Fuels Conference in Bologna May 2016.

Most European countries are promoting bio gas to be upgraded and injected into the existing natural gas grid and are providing funds for bio methane production, subsidies in the form of direct support for investment and/or high Feed In Tariffs (FIT) for the bio methane.

The state of Italy is providing a subsidy for all projects that generate methane gas from gas from agricultural and zootechnic raw materials.

Under current Italian government guidelines, the Ministerial Decree of 2 March 2018, agricultural and zootechnic raw materials are considered preferential sources to generate bio methane.

A total production of 2.3 billion m3 of bio methane will be subsidized for 15 years for those plants which enter production within 30 June 2026.

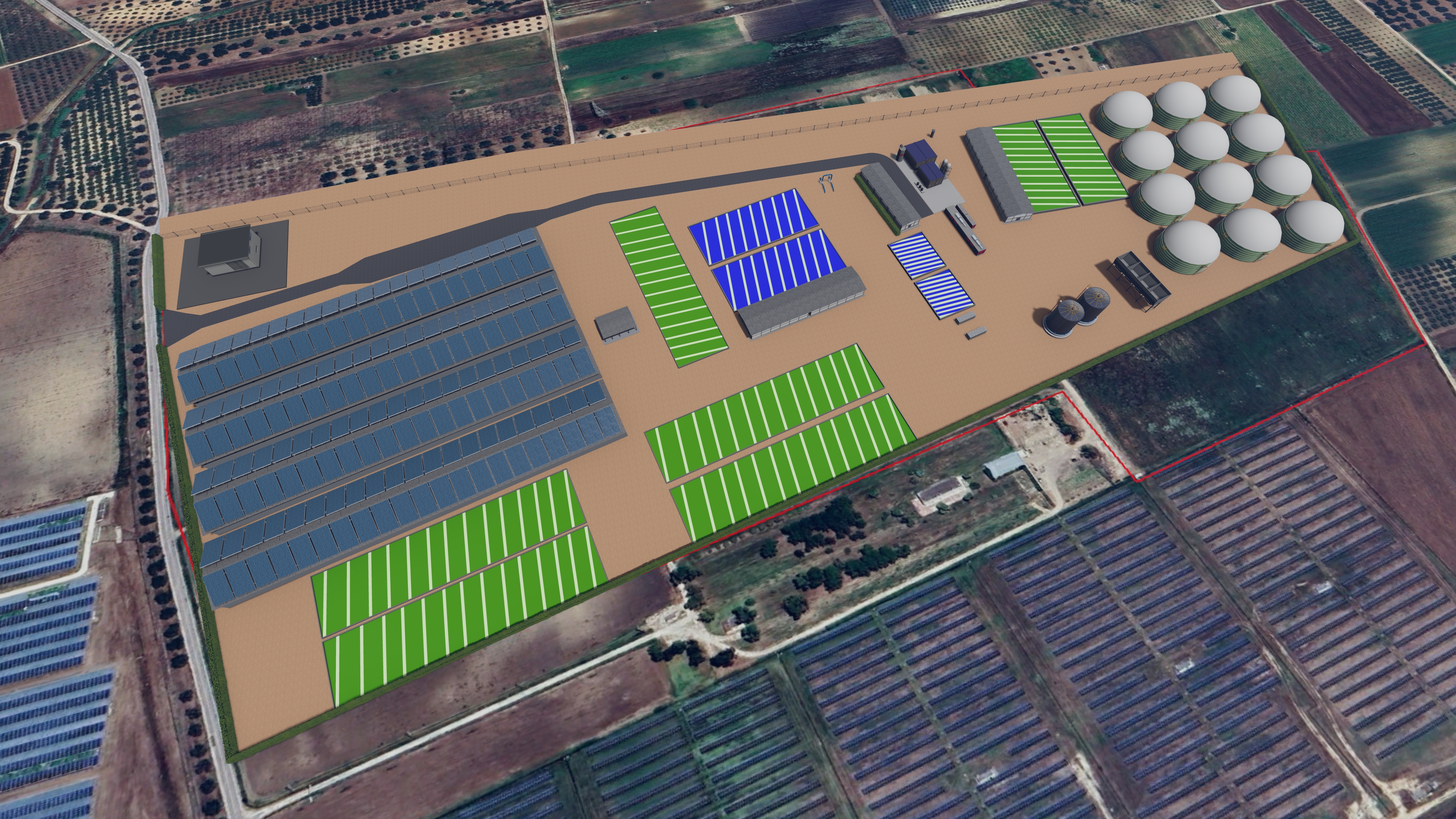

The first project is proposed to be set up in the Region of Puglia to generate 24 million cubic meters of bio methane per annum. This bio methane is being generated to supply the Italian transportation sector and industry.

At present, in the south of Italy there is not a single plant with a capacity of more than 10 million cubic meters that has been announced to produce bio methane from agricultural residues for transportation fuel and industrial use

In the next year, the company intends to develop an identical facility in Sicily, to produce Bio Methane.

Deloitte Italy have prepared an information memorandum.

Construction is set to start in the 2nd quarter of 2025 and Bio methane production in the 2nd quarter of 2026.

The total project investment to produce Green Bio Methane is budgeted to be 70 million euro.

PROCESS DESCRIPTION

This project is divided into 5 phases.

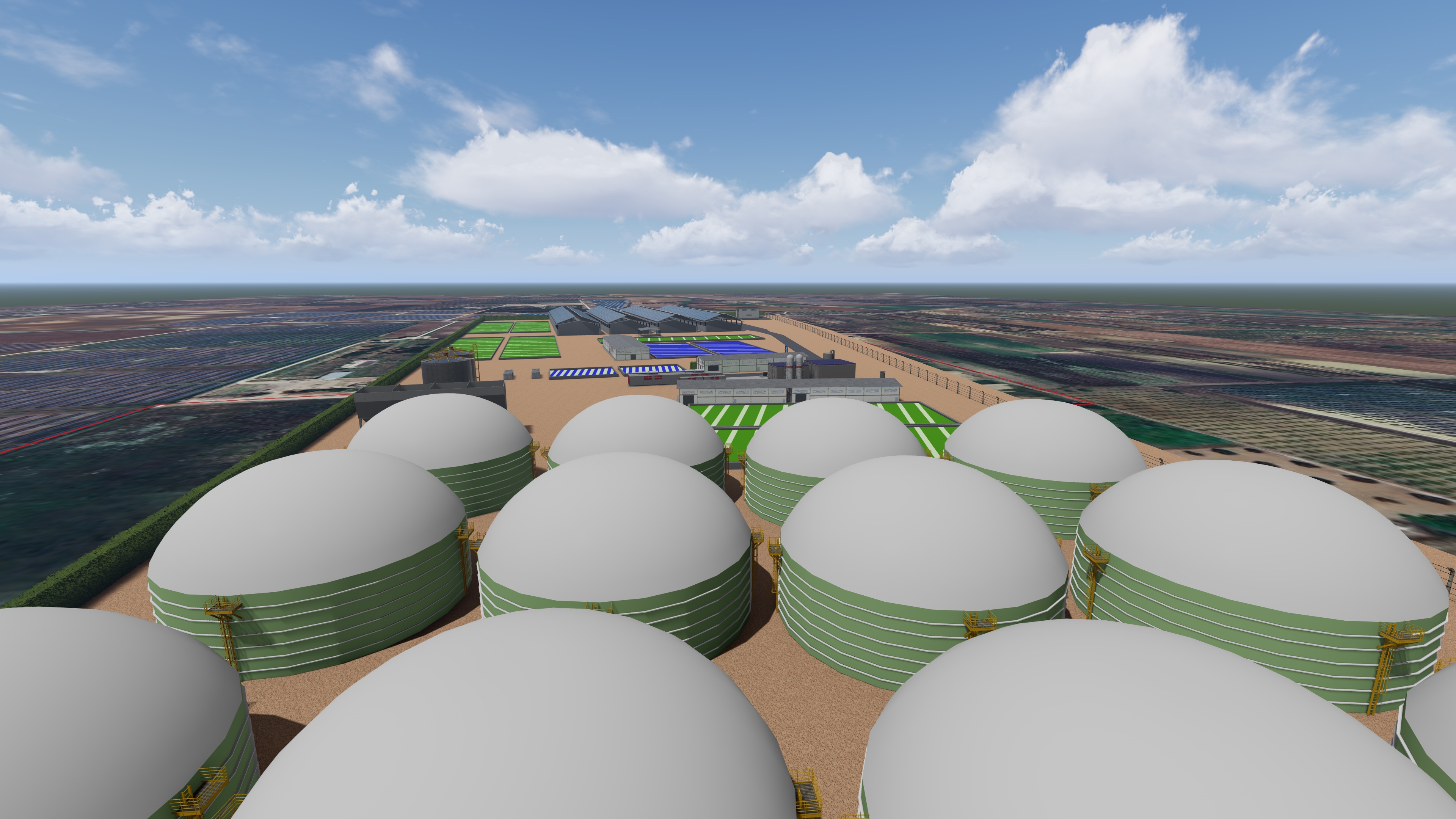

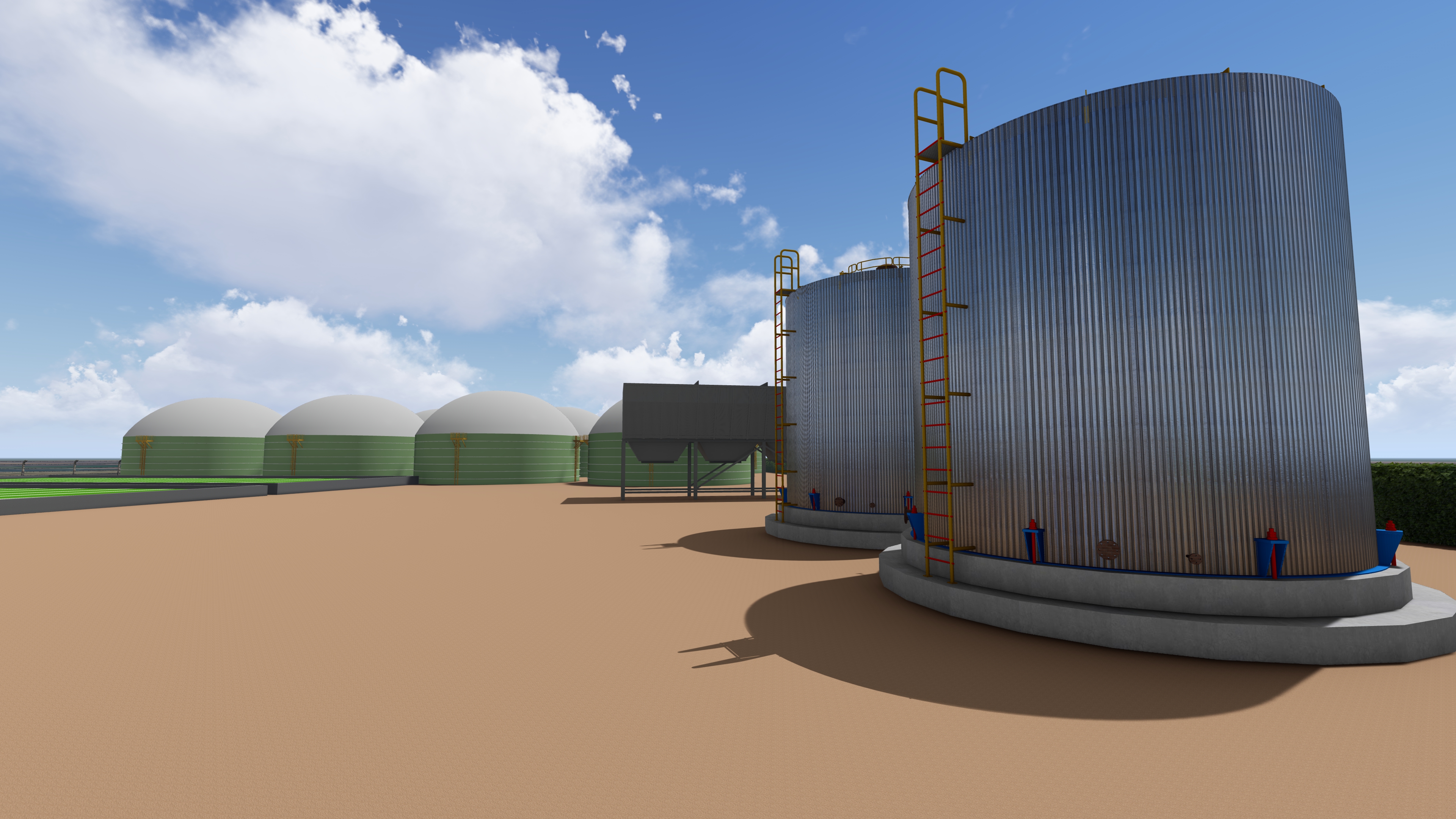

1. Converting the agricultural residues through an anaerobic digestion process into bio gas.

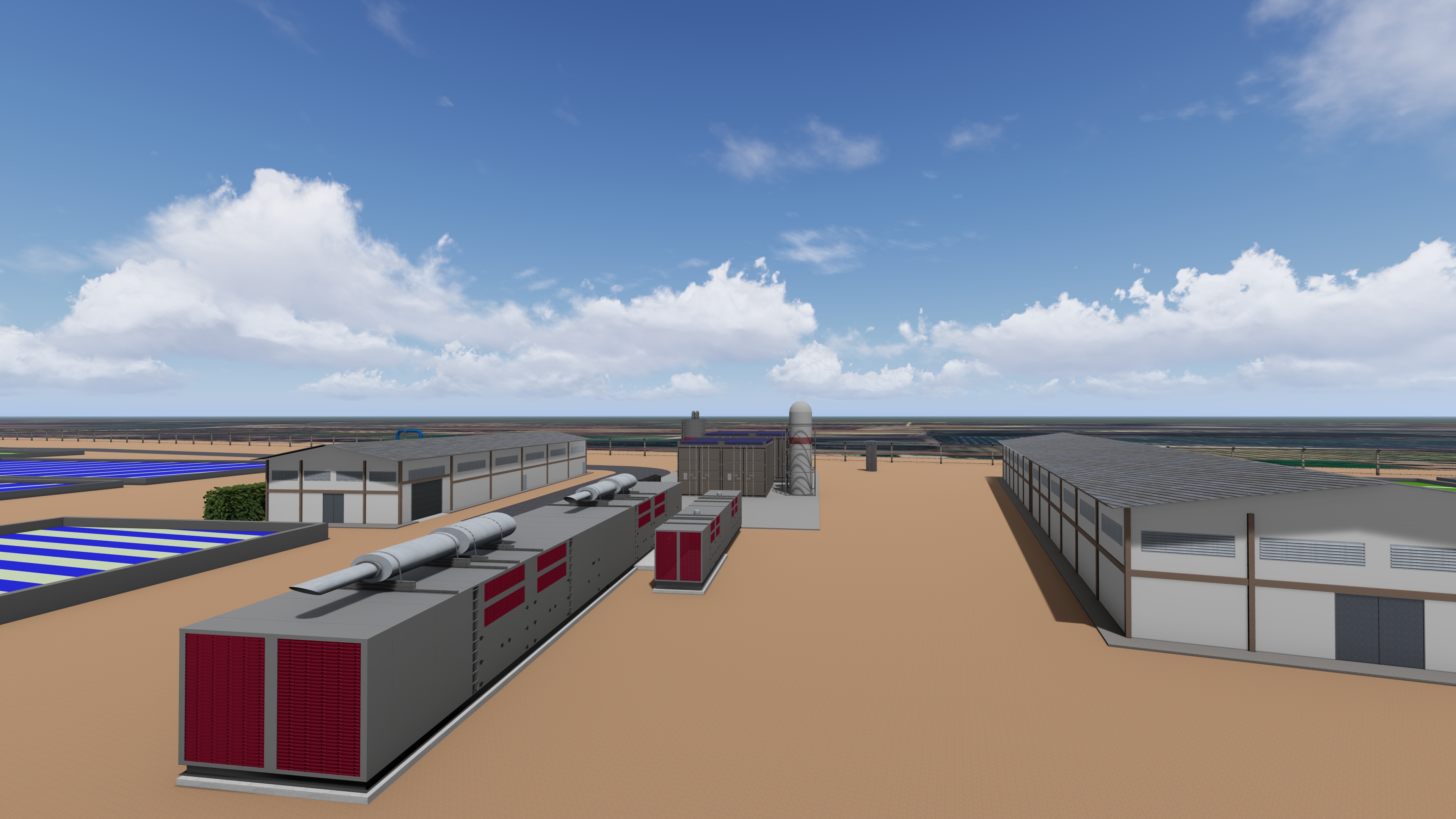

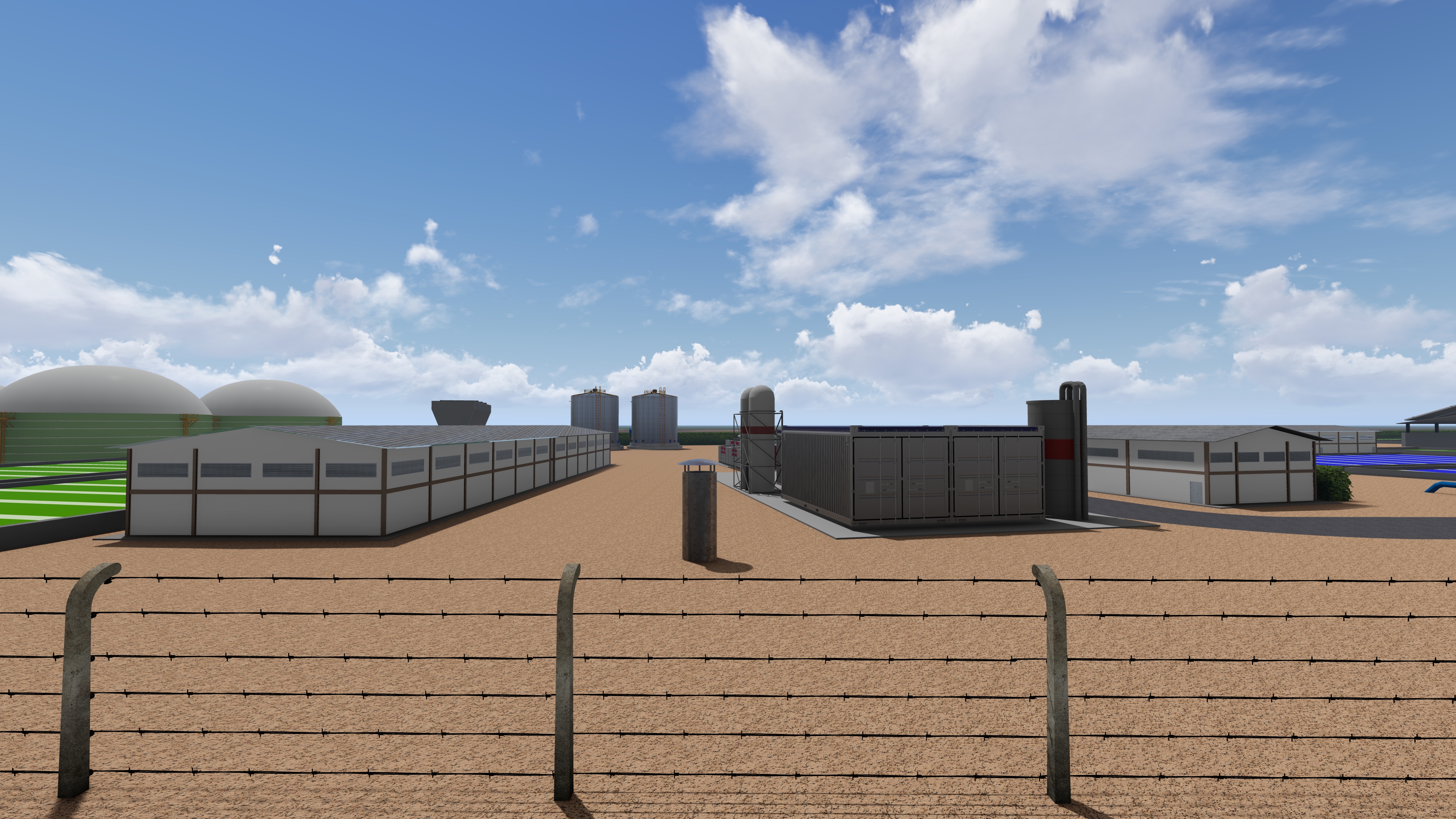

2. Cleaning the bio gas to obtain bio methane.

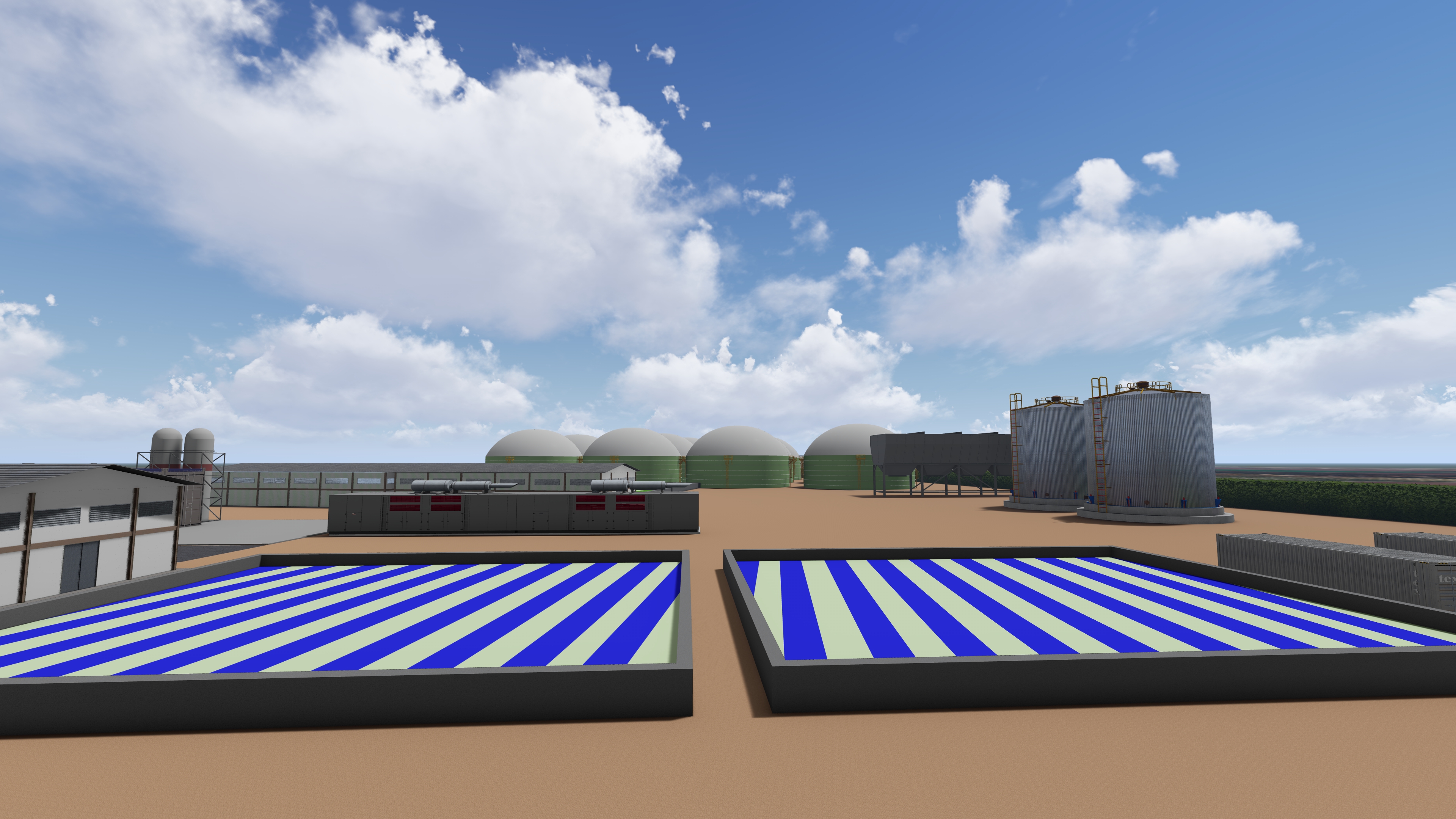

3. Liquefaction of CO2.

4. Converting the residual digestate to organic fertilizer pellets.

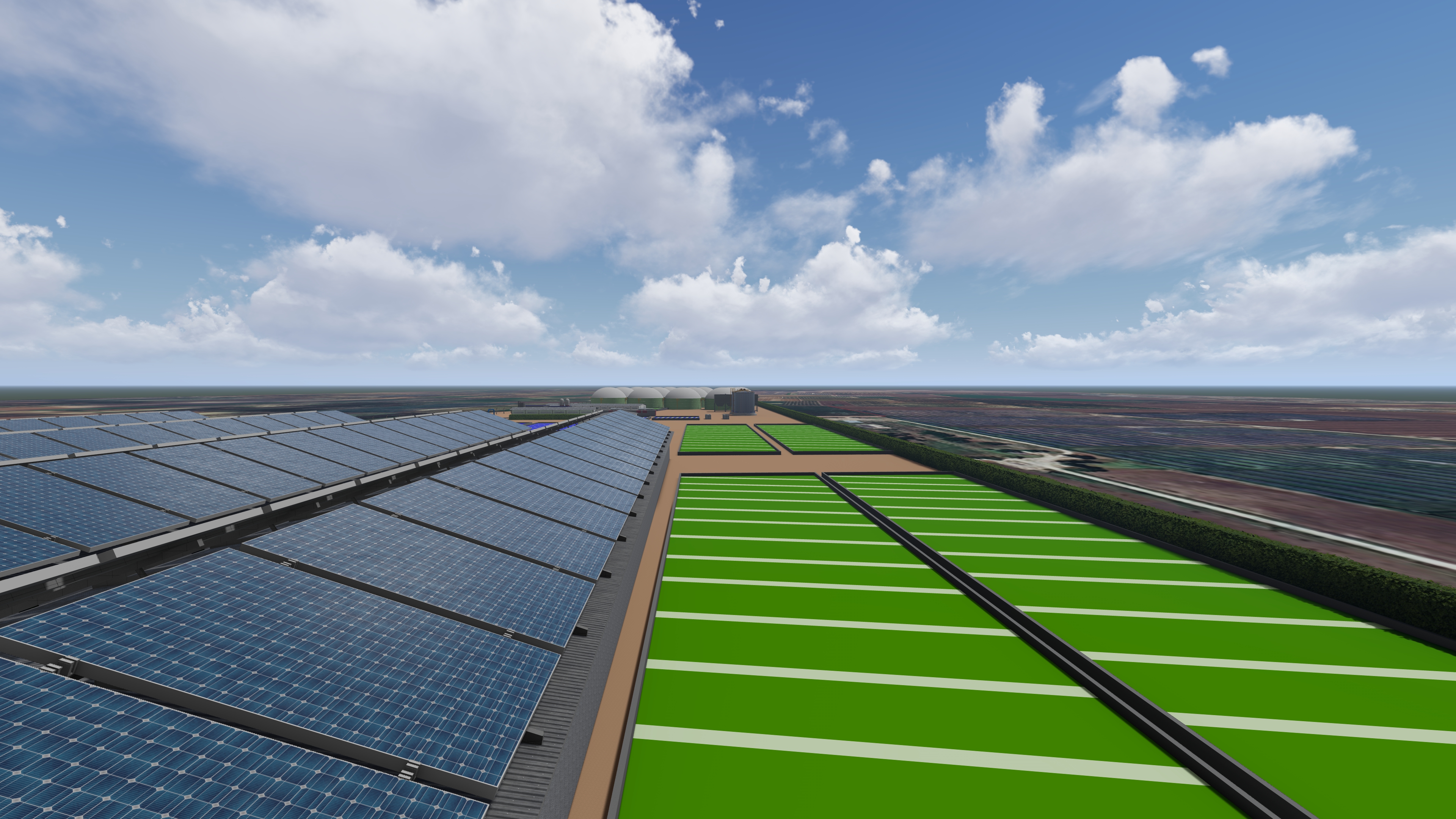

5. Within the next two years setting up an in.house plantation to grow an energy crop to replace third party feed stock supplies.

The conditioned agricultural residue biomass will then enter the anaerobic digestion section where it will be fermented for 4-6 weeks and subsequently attacked by suitably chosen enzymes which will convert the contained lipids and proteins into methane and CO2.

This resulting bio-gas has a composition of about 50%-60% methane (CH4) and 40%-50% Carbon dioxide (CO2) with lesser quantities of hydrogen sulphide (H2S) and nitrogen compounds. This bio gas will then be fed through a series of gas scrubbing systems which will remove in separate steps the H2S, N compounds and the CO2 leaving a purified bio-methane of 99%+ CH4.

The digestate resulting from the anaerobic digestion will be seasoned and converted to organic fertilizer pellets

During the cleaning process, the CO2 will be collected and treated. It is then liquefied and sold for industrial use.

Key Milestones:

- Technical team in place.

- All Engineering parameters settled.

- Region of Puglia has welcomed and appreciated the benefits of this project to the community. The local authorities have examined the project and informally determined that the project does not have any negative effect on the environment and therefore, building permissions shall be issued after all mandatory documentation is submitted.

- The permitting application was submitted in June 2021. Authorisation Unica acquired on August 1st 2024.

- EPC contract finalized with a reputable engineering company that has built over 290 similar plants, that will provide a 100 % completion guarantee thereby ensuring project will be built on time and within budget contracted .

Such a guarantee will mitigate the construction risk. - O & M (Operations and Management) contract signed with the EPC contractor for 2 years, extendable to 5.

- In Mesagna, near Brindisi, Puglia, South Italy, 32 hectares of land have been acquired with the SNAM pipeline traversing the property.

- Competitive offers have been received for anaerobic digesters and other equipment.

- Initial Communication received from an accredited agency manifesting this project to comply with green principles as laid down by the United Nations / European Union.

- Kick off meeting held with officials responsible for processing environment approvals and it has been agreed that no Environmental impact assessment report is needed as project does not flout any norms.

- Company Capitalized to the extent of 5 M.

- Negotiations in process with a leading Insurance broker for arranging a package of insurance policies to cover construction risk, contract frustration, business interruption and other insurable events.

- Algae & Algae Società Agricola rl constituted at Milan, Italy in September 2020, as an agricultural company enabling a low tax regime to be applied. This company is the SPV that will own and operate the projects.

- 5-year contract for obtaining agricultural substrates executed and is renewable for another 5. This is the main raw material for the years 2026 – 2030.

- ITR (Independent Technical Report) commissioned with a reputable company.

- The company has signed in August 2024 contract with Italian state gas pipeline owner SNAM for connection to the gas grid.

- The company has been awarded on Oct 30th a financial subsidy akin to a feed-in contract for 15 years by the Italian state, for a total amount of €228 M, as well as a grant contribution of €7.5 M

- The project Greenhouse-Gas (GHG) Reference ( carbon index ) is ( minus ) -50 gCO2eq/MJ

The Eventual Objective.

There is a large requirement in the EU for decarbonized fuel. Such projects are being assisted by various financing mechanisms.

Algae & Algae has a technically advanced production model for bio methane from locally sourced agricultural by-products.

This can be achieved at comparatively low capital investment and low operating cost thereby ensuring robust cash flow generation and high return on equity.

The demand for decarbonized fuel transport fuel continues to rise in the EU. The Company is at the forefront of Bio Methane as a means of providing a sustainable green fuel.

The plan is to setup additional facilities in the EU with the eventual objective of having a substantial capacity to produce Bio Methane.

In Summary

|

- Under the existing legislation the Italian State is obliged to provide a price support mechanism for the first 15 years of production.

- The Italian State is obliged to give financial incentive during the period of 15 years on every cubic meter of bio methane produced in the form of a price support mechanism. This price support mechanism is valued at around 127 cents per cubic meter. On October 30th 2024, the Italian state Entity GSE, has granted the project an operational financial support that guarantees Phase 1 of the project with a revenue os 127 cents per cubic meter of biomethane. The financial support shall cover 12 million cubic meters of biomethane per year, pertaining to Phase 1 over the first 15 years of operations. Phase 2 shall also have an installed capacity of 12 million cubic meters per annum and financial support equal to the same value as Phase 1 is expected to be awarded in the latter part of 2025 for the 2nd phase.

- The main feed stock for the first 5 years of operation is locally available and has been secured via a 5 year contract and is renewable for another 5.

- The company shall cultivate its own energy crop in-house at competitive costs, thereby removing insecurity of raw material supply, which is a key risk facing most industrial projects.

Parameters 1 - 4 above assure financial viability of this project.

- The project meets principle goals set by the European Union towards green energy and mitigation of climate change.

|

This Project Provides the Following Benefits to The Community:

(A). Promotes green energy and produces non fossil fuel-based gas that is welcomed by the general population in Europe.

(B). It contributes to the reduction of global warming.

(C). The bio methane is to be used as transportation fuel in cars and industry in general and when liquefied is used as LNG in trucks and heavy vehicles that vastly reduces emissions emanating from vehicular traffic.

(D). Subsequently a portion of the organic material being cultivated, can be used in the pharmaceutical industry thereby having a positive social effect on society.

(E). The bio mass residue left over can be used as bio fertilizer.

(F). Provides employment in areas where it is most needed.

(G). Reduces the need to use bio mass of agricultural crops for conversion to energy.

(H). The operations of this project will bring about a reduction per annum of 50,000 MT of CO2 / CO2 equivalent

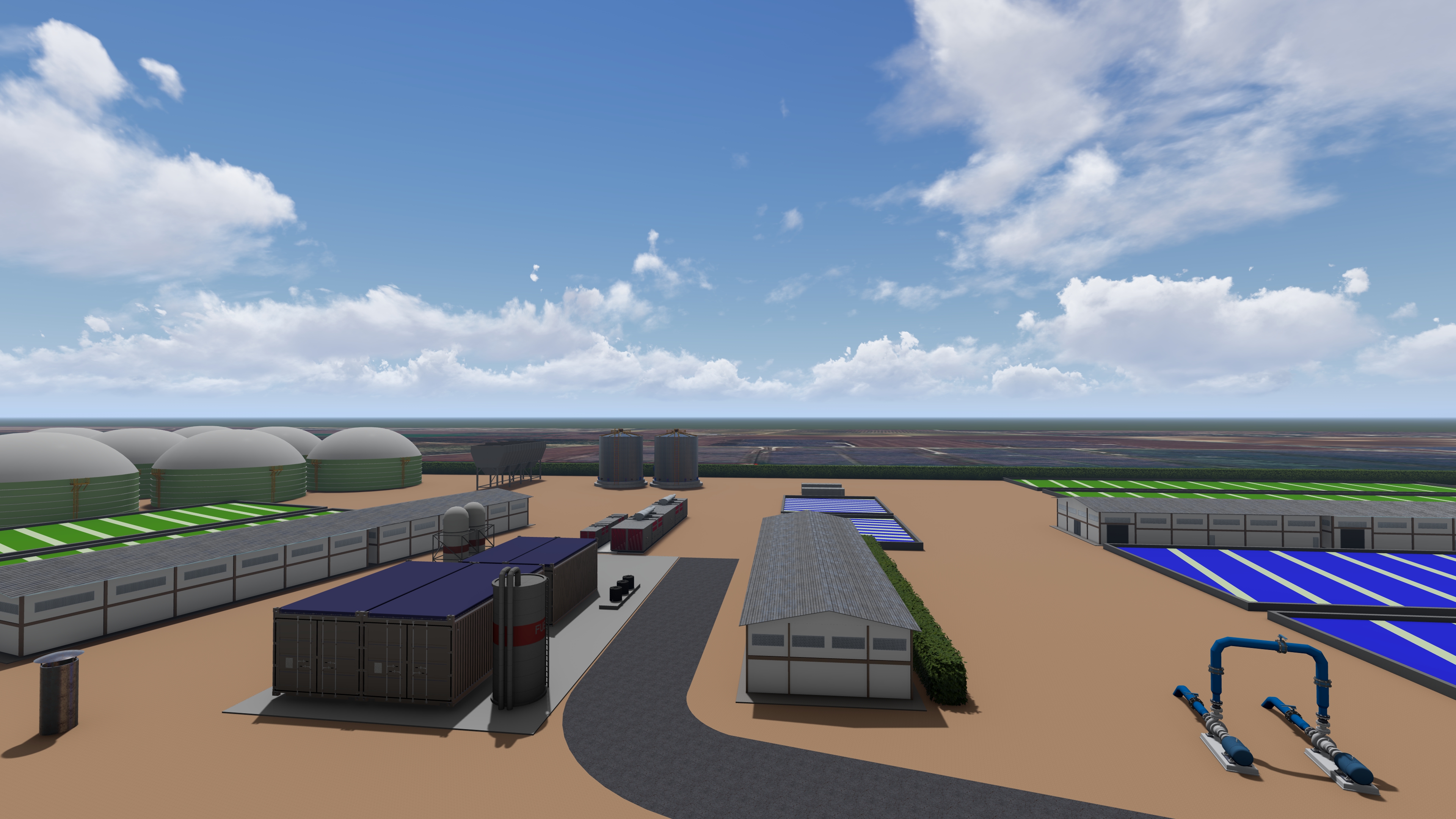

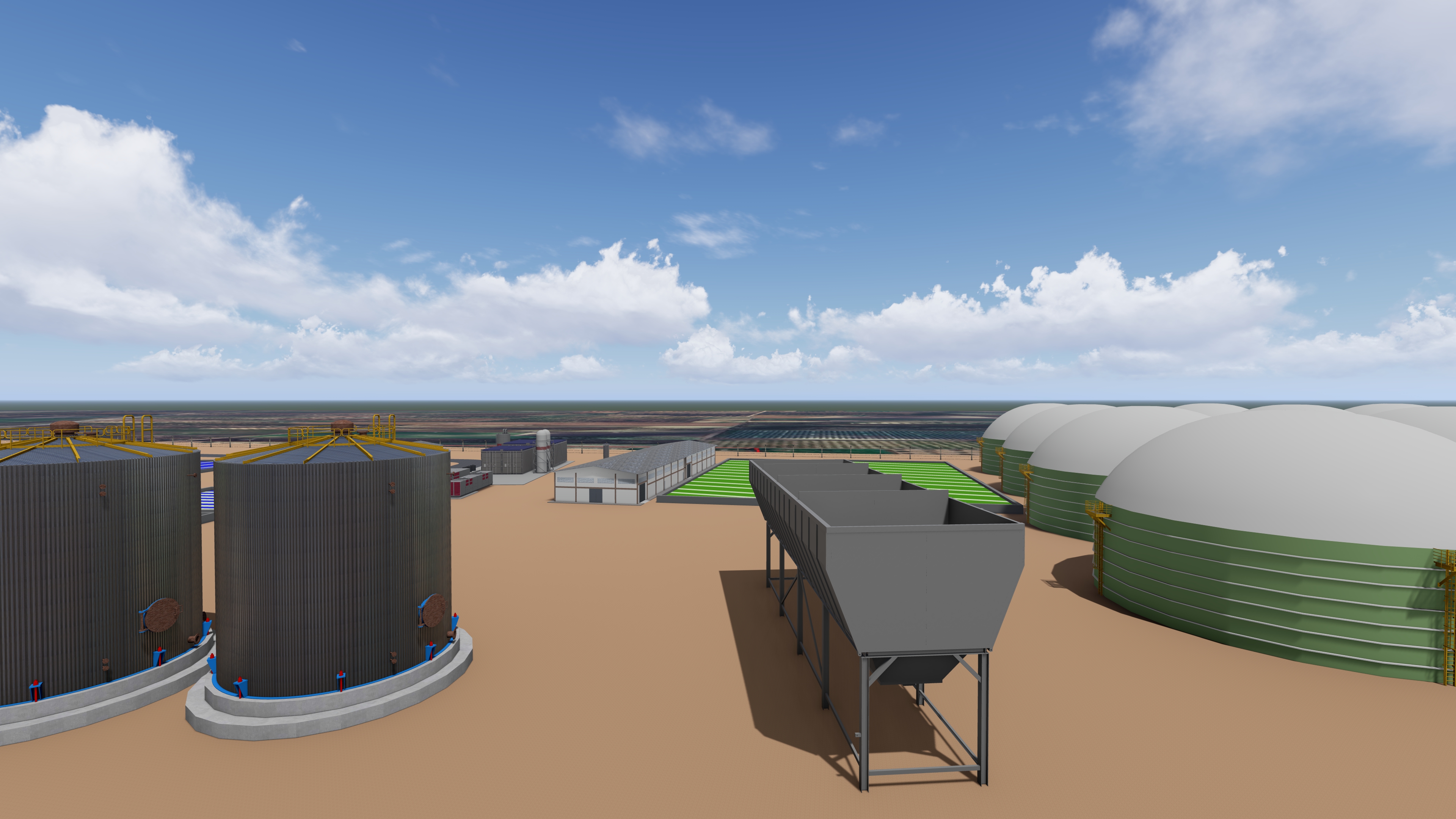

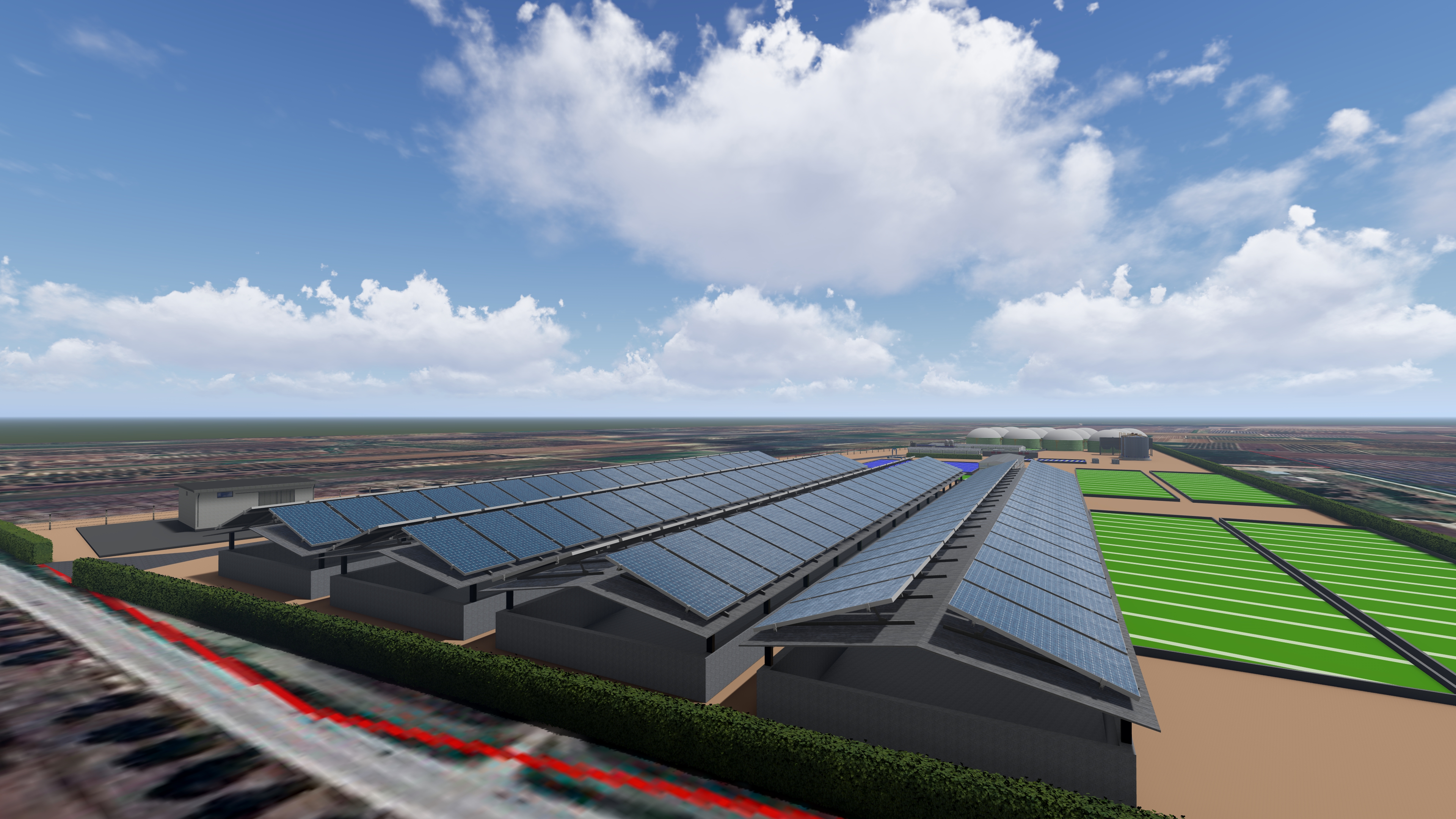

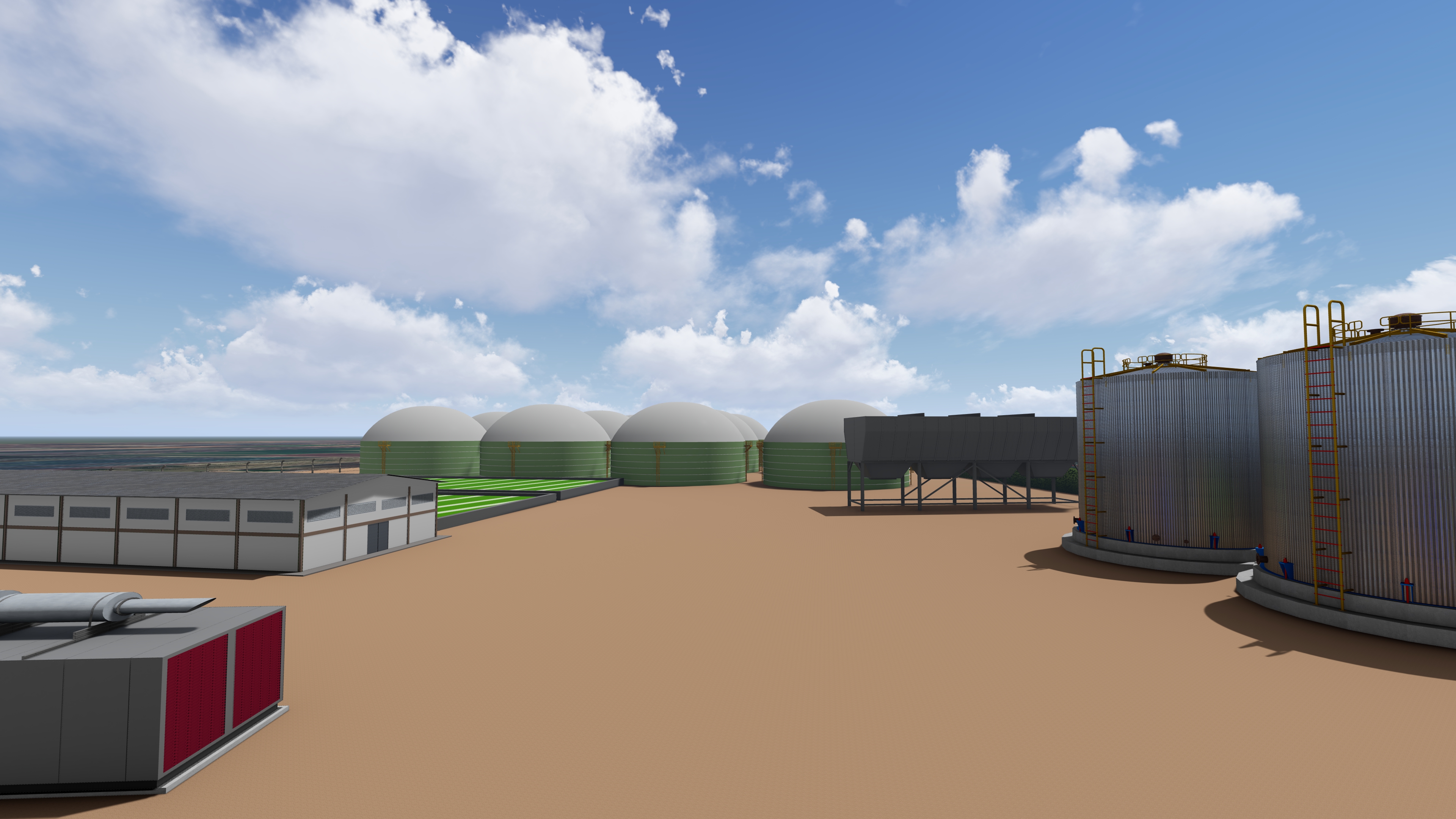

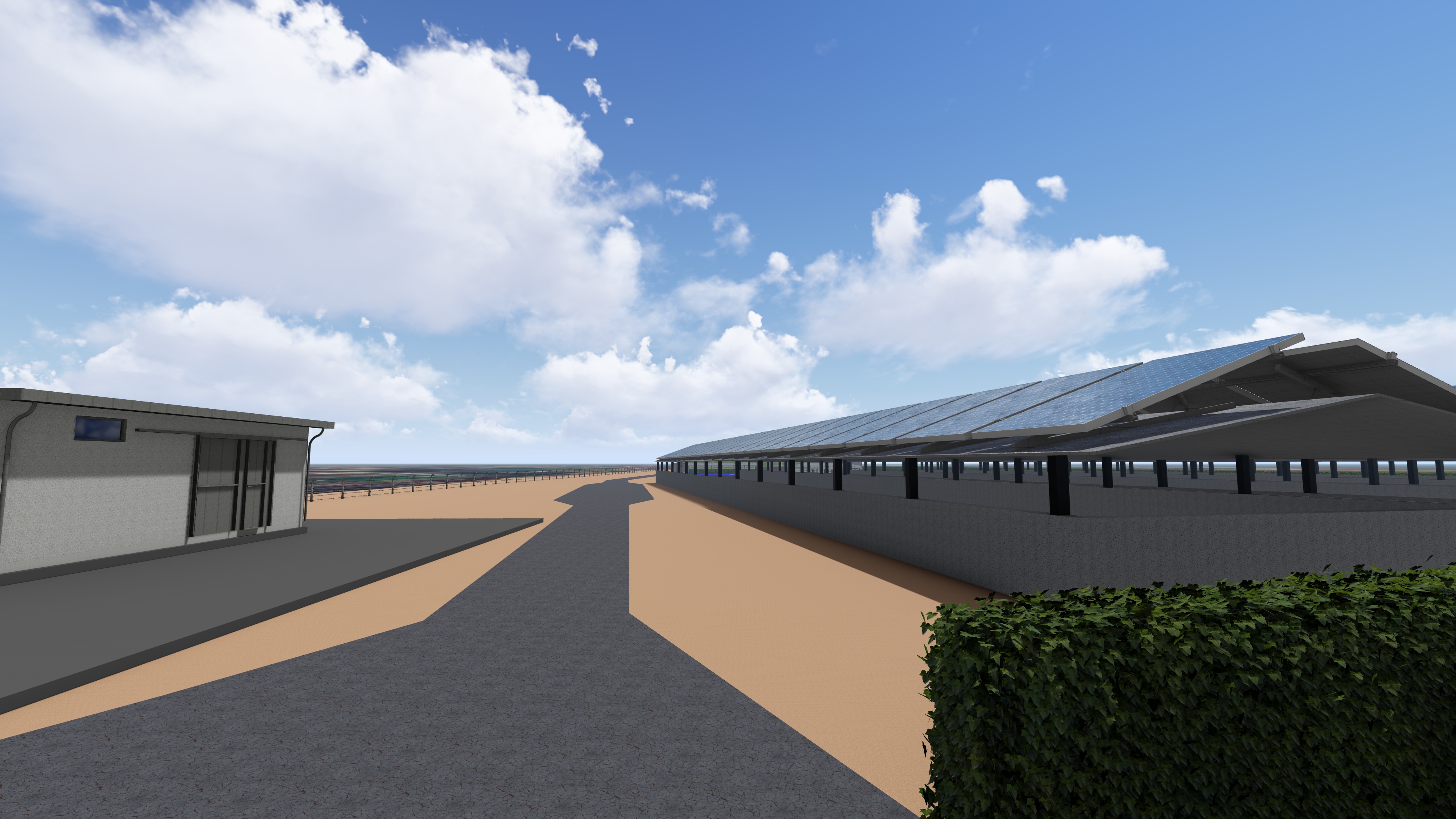

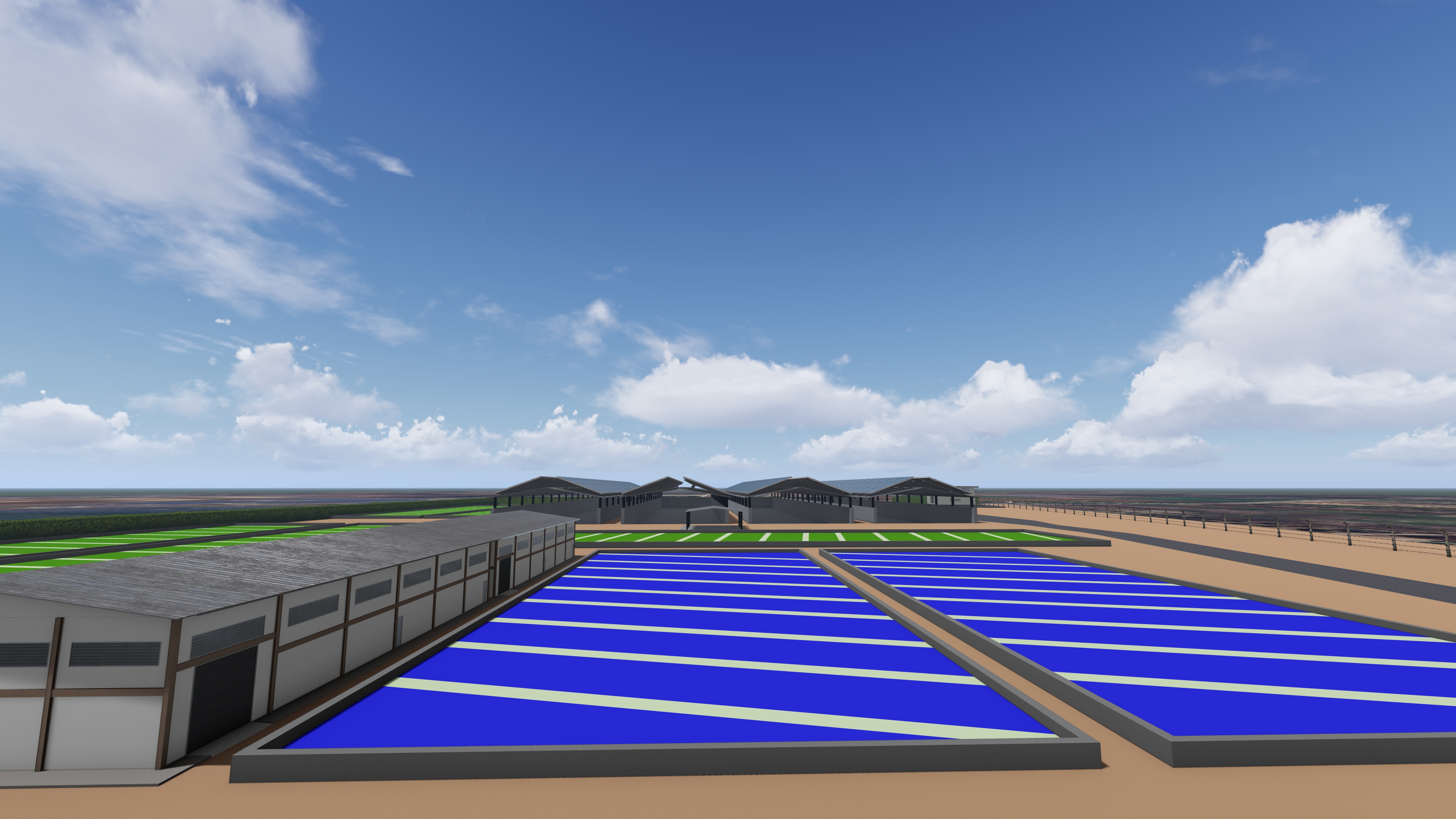

Below is a 3D visual presentation of the project.

|

HERE IS ALSO A VIDEO REPRESENTATION OF THE PLANT:

CONTACT:

Should you have any questions ,wish to discuss any type of collaboration with us please contact us at the below address:

ALGAE & ALGAE SOCIETÀ AGRICOLA RL

IVA: 11390170964

N. REA MI-2598992

Address: Via C.Colombo–Res.Ponte 142, 20080 Basiglio, Italia

Email: projectcoordinator@algaealgae.com